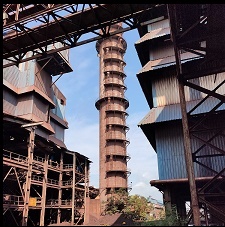

OUR BENEFICIATION PLANT

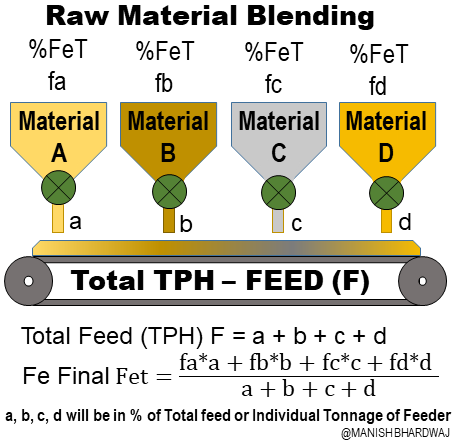

Beneficiation is a technology for agglomeration of low grade iron ore fines into useful material for pellet plant. A process adapt to up grade ore is called Beneficiation. The good quality iron ore is fast depleting thereby forcing the iron makers to use beneficiation.